Detailed on Thread Gage Calibration

Thread Gage Calibration is a typical technique for calibration of Thread rings. These measures must be aligned on a periodical premise in order to check if the checks are as yet in its usable size range.

At the point when another ring measure is made, we from the outset would need to check for the accompanying things:

1. If the gage calibration is right?

2. How much would the ring have exhausted after a specific utilization?

3. What is the down to earth way out?

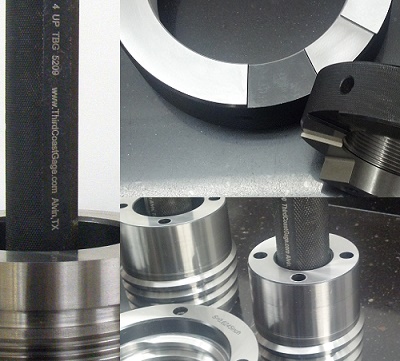

So as to discover responds to for the above inquiry, this is the place "check plug measures" comes into the image. The attachment gage is fundamentally used to check the rightness of the pitch measurement. Another Thread ring is only a nut with close resilience. Consequently, this new nut can be assessed by the attachment check which has severe resistances. This is the thing that the Thread plug measure it made for.

• Once we have checked the Thread ring for its resiliences, we at that point need to check GO and NO-GO. This is utilized for checking shafts and openings in the gages. This technique is straightforward and straightforward. This strategy fundamentally informs us as to whether the screws or the nuts are can be acknowledged for additional utilization.

• Once we have checked the gage for the GO and NO-GO, we at that point require one wear check plug for each Thread ring. In this progression, the wear register plug can't enter with the Thread ring more than one turn as it is a NO-GO gadget.

• The subsequent stage is to modify the Thread rings with the goal that they can be set to the right size. To do as such, there will be a GO estimated setting gage and a NO-GO size setting gage for the Thread ring measures. After it has been set, these rings at that point would need to be checked with their separate check plugs for non-section.

• The second last advance is to set up plugs for Thread caliper measures. This technique is utilized to check if the setting measures go easily through the checks utilizing gravity alone.

• The last advance is then to outwardly check the ring to distinguish the pitch of a strung part utilizing the Thread pitch measure.

With the assistance of the above advances, it will get simpler to discover the right calibration of the Thread gage.

Comments

Post a Comment