Manual to Calibrate Drill

You can begin by aligning the drill for a driving distance of 200 feet. Take an irregular length, however it ought to be sufficiently long to catch fluctuation in the field. In any case, it's not very long to be pointless. In this manner, you should conclude the width embedded by your drill. In this occasion, we will discuss a drill with a functioning width of 10 feet. Working width is assessed by increasing the dividing between seed openers by the digit of openers on the drill.

The region cultivated in standard will be 2,000 square feet. To assess the measure of a section of land, peak 2,000 square feet by 43,500 square feet for each section of land. It is to arrive at a space of 0.046 sections of land.

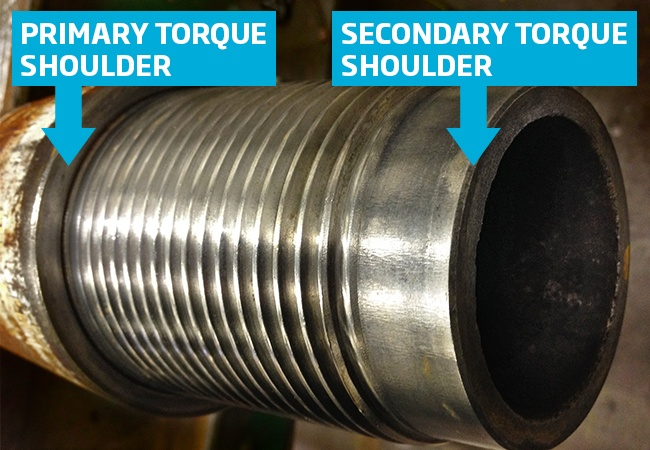

You should confine the number of disturbances of the seed drill drive wheel when aligning distance. To start with, in the field, utilize an estimating tape or one more estimating device to gauge a circuit that is 200 feet long. Then, at that point, gather which wheel is trustworthy for driving the cultivating component on the Rotary Shouldered Connection. On a couple of drills, this will be a private wheel that essentially runs the seed metering system. In the meantime, on different drills, it will be one of the wheels that helps the drill.

You are needed to choose the number of upsets this wheel gets the field in a 200-foot length. To start with, leave an imprint or relate a piece of weighty tape to the wheel to urge you to count wheel transformations while driving without any problem. Then, drive 200 feet, which you some time ago set apart out in the field, and count the number of disturbances made during the 200 feet. For further developed precision, rehash this a couple of times and utilize the API 7-2.

Setting Up The Drill For Calibration

Fixed alignment is directed by recreating drill activity. The seed discharge arrangement of the drill. It is represented definitively when being pulled across the field by spinning the drive wheel; the quantity of not set in stone.

By and large, Stationary alignment is executed by lifting the drive wheel over the dirt surface. So it can turn as needs be. A modest bunch of pressure-driven shop jacks is frequently used to satisfy this. Limit the drill safely. Make it joined to the farm hauler to reinforce a degree of wellbeing while extending the drive wheel. Additionally, to work the power through pressure on the drill.

It is consistently important to bring down the drill. It approves the drive system to become drenched so that cultivating rate adjustment can be performed.

Resourced by: https://bit.ly/3omoSTX

Comments

Post a Comment